What is injection molding slider?

Due to the special requirements of a product. The mold release direction of a particular part may not be consistent with the mold opening direction of the injection molding machine (product undercut). A slider is a molding machine that is developed to solve the issues with the undercut.

Basic Principles of the Slider

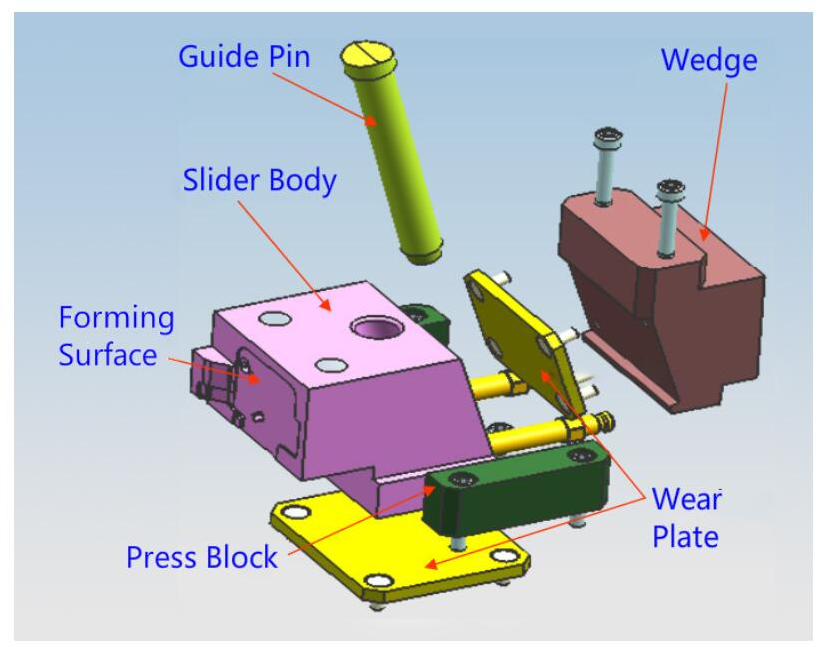

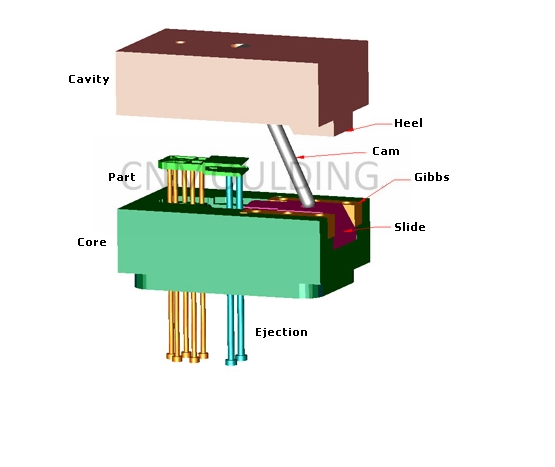

Due to the special requirements of a product, the mold release direction of a particular part may not be consistent with the mold opening direction of the injection molding machine (product undercut). A slider is a molding machine that is developed to solve the issues with the undercut. The basic principle is to turn the vertical movement of mold opening/closing into horizontal motion. In order to cope with the situation that the undercut is located in the core or cavity, different structural forms are developed.

When it comes to injection molding, the design of the slider is critical to the success of the process. A slider is a component of the mold that moves in a direction perpendicular to the opening and closing of the mold. It is responsible for creating undercuts in the final product, which is essential for many injection molding applications.

The design of the slider needs to be carefully considered to ensure that it functions correctly and produces high-quality parts. There are several factors that need to be taken into account when designing an injection mold slider.

Firstly, the material that the slider is made from needs to be carefully chosen. The material needs to be strong enough to withstand the forces that are applied to it during the injection molding process. It also needs to be wear-resistant, as the slider will be moving back and forth many times during each cycle of the mold.

The shape of the slider is also important. It needs to be designed in such a way that it can move smoothly and easily within the mold. This means that the shape needs to be carefully optimized to minimize friction and reduce wear.

Another important consideration is the mechanism that is used to move the slider. There are several different types of mechanisms that can be used, including hydraulic, pneumatic, and mechanical. The choice of mechanism will depend on a range of factors, including the size and complexity of the mold, as well as the specific requirements of the application.

The placement of the slider within the mold is also critical. It needs to be positioned in such a way that it can create the required undercuts in the final product. This means that the position of the slider needs to be carefully planned and optimized during the design process.

Finally, it is important to consider how the slider will be maintained and serviced over time. The slider will experience wear and tear over time, so it needs to be designed in such a way that it can be easily replaced or repaired when necessary.

In conclusion, the design of an injection mold slider is a critical factor in the success of any injection molding process. By carefully considering factors such as material choice, shape, mechanism, placement, and maintenance, it is possible to design a slider that functions correctly and produces high-quality parts. With careful planning and attention to detail, it is possible to create injection molds that deliver excellent results time and time again.

As a professional china injection mold company, we focus on precision mold making manufacturing

in china for the complicated slider.