Flame Retardant Plastic Injection Molding for New Energy Vehicles (NEVs)

As the automotive industry shifts toward electrification, the demand for high-performance flame retardant (FR) plastic materials has surged. In New Energy Vehicles (NEVs), safety is paramount—especially within battery systems and charging infrastructure. At CNMOULDING, we provide precision injection molding services using advanced FR polymers to ensure the highest safety and performance standards.

Key Applications of FR Plastics in EV Components

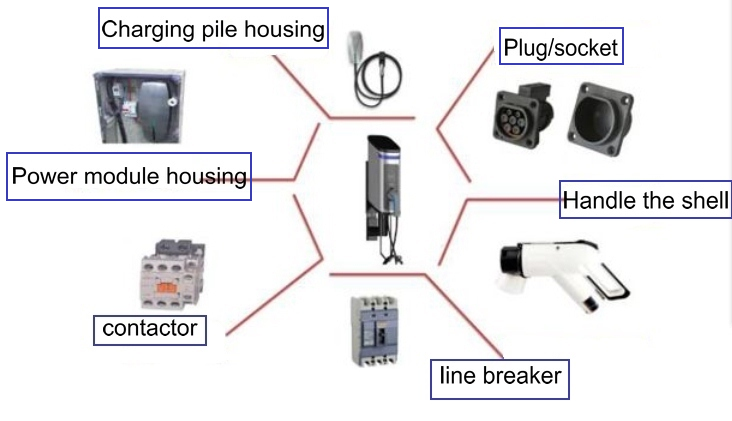

1. EV Charging Infrastructure (Guns & Piles)

Charging connectors and stations require materials with superior insulation and weather resistance.

- Charging Guns: Typically molded from PBT+GF, PA+GF, or weather-resistant PC. These materials handle high-frequency plugging while maintaining structural integrity.

- Charging Pile Shells: We utilize halogen-free flame retardant PC, offering high gloss, excellent electrical insulation, and impact resistance.

2. Battery Modules & Power Battery Housings

Modern power batteries are transitioning from metal to plastic shells to reduce weight and improve insulation.

- Material Requirements: Our battery housings meet strict flame-retardant standards to prevent thermal runaway.

- Common Materials: Reinforced PPS, PPE, or FR-PA are used for their thermal stability and chemical resistance.

3. High-Voltage Connectors

Connectors are the “nervous system” of an EV. To prevent electrical fires during high-current transmission, we use high-heat resistant materials like PPS, PBT, and PET. These ensure reliable performance over thousands of mating cycles.

4. Specialized Automotive Wiring & Cables

EV charging cables must withstand high temperatures and environmental aging. We process halogen-free, low-smoke (LSZH) materials that provide excellent flexibility and insulation without compromising on safety.

Why Choose Plastic Over Metal for Auto Parts?

Switching to engineering plastics offers significant competitive advantages for automotive OEMs:

- Lightweighting: Every 10% reduction in vehicle weight improves fuel/battery economy by approximately 5%, extending the driving range of EVs.

- Cost Efficiency: Injection molding allows for complex, integrated designs, reducing the need for multiple metal stampings and welding processes.

- Safety & Buffering: Plastics possess elastic deformation properties that absorb collision energy, enhancing passenger protection.

- Corrosion Resistance: Unlike steel, plastic components are immune to rust and chemical degradation, ensuring a longer vehicle lifespan.

Your Partner in Automotive Plastic Excellence

With 28+ years of experience, CNMOULDING specializes in custom injection molding for the automotive sector. From material selection (PEEK, PPS, PC/ABS) to high-precision mold tool making, we help you accelerate the development of safe, efficient, and lightweight New Energy Vehicles.