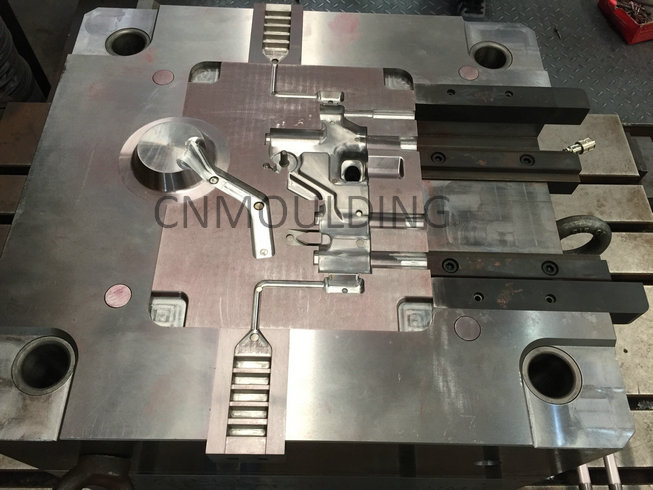

Die casting is a metal casting process that involves forcing molten metal under high pressure into a mold cavity, called a die. The die is typically made of hardened tool steel and is reusable. Die casting is widely used in manufacturing for producing high-volume, precision metal parts with excellent surface finish and dimensional consistency.

Key Features of Die Casting:

- High Pressure Injection – Molten metal is injected at high speed (up to 100 m/s) and pressure (up to 1,000+ bar).

- Reusable Molds (Dies) – The dies can be used thousands of times before needing replacement.

- High Production Rate – Ideal for mass production due to fast cycle times.

- Excellent Precision & Surface Finish – Parts often require little to no machining after casting.

- Thin-Walled Components – Capable of producing complex shapes with thin walls.

Common Metals Used:

- Aluminum (lightweight, corrosion-resistant)

- Zinc (high strength, good for small parts)

- Magnesium (ultra-lightweight)

- Copper & Brass (high conductivity)

- Lead & Tin (low melting point applications)

Types of Die Casting:

- Hot-Chamber Die Casting

- Used for low-melting-point metals (zinc, lead, tin).

- The injection system is submerged in molten metal.

- Faster cycle times.

- Cold-Chamber Die Casting

- Used for high-melting-point metals (aluminum, copper).

- Molten metal is ladled into the injection chamber.

- Higher pressure required.

Advantages:

High production efficiency

Tight tolerances (±0.1 mm or better)

Smooth surface finish (can eliminate machining)

Complex shapes achievable

Good mechanical properties

Disadvantages:

High initial die cost (not economical for small batches)

Limited to non-ferrous metals (typically)

Porosity can occur in thick sections

Applications:

- Automotive (engine parts, transmission housings)

- Aerospace (lightweight components)

- Electronics (heat sinks, connectors)

- Consumer Goods (appliance parts, power tools)

- Medical Devices (surgical instruments)

Die Casting vs. Other Casting Methods:

| Feature | Die Casting | Sand Casting | Investment Casting |

|---|---|---|---|

| Surface Finish | Excellent | Rough | Very Good |

| Tolerance | Very High | Low | High |

| Production Rate | Very Fast | Slow | Moderate |

| Cost (High Volume) | Low | Low | High |

| Material Flexibility | Non-ferrous | All metals | All metals |

Die casting is ideal for industries requiring high precision, repeatability, and fast production of metal parts. Would you like details on a specific aspect, such as die design or defect prevention?